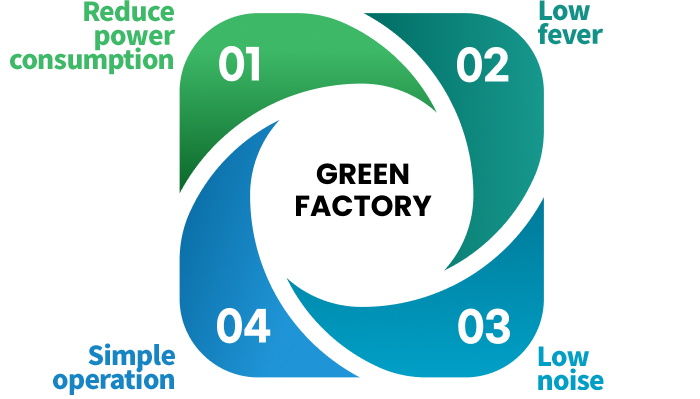

Reduce power consumption

Low fever

Low noise

Simple operation

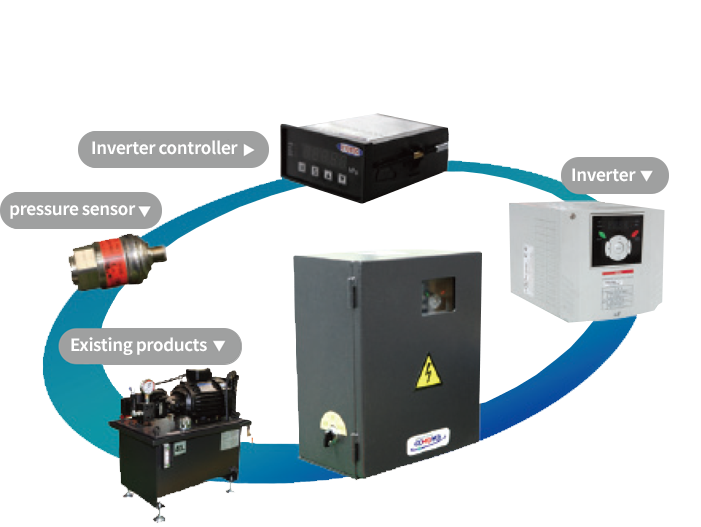

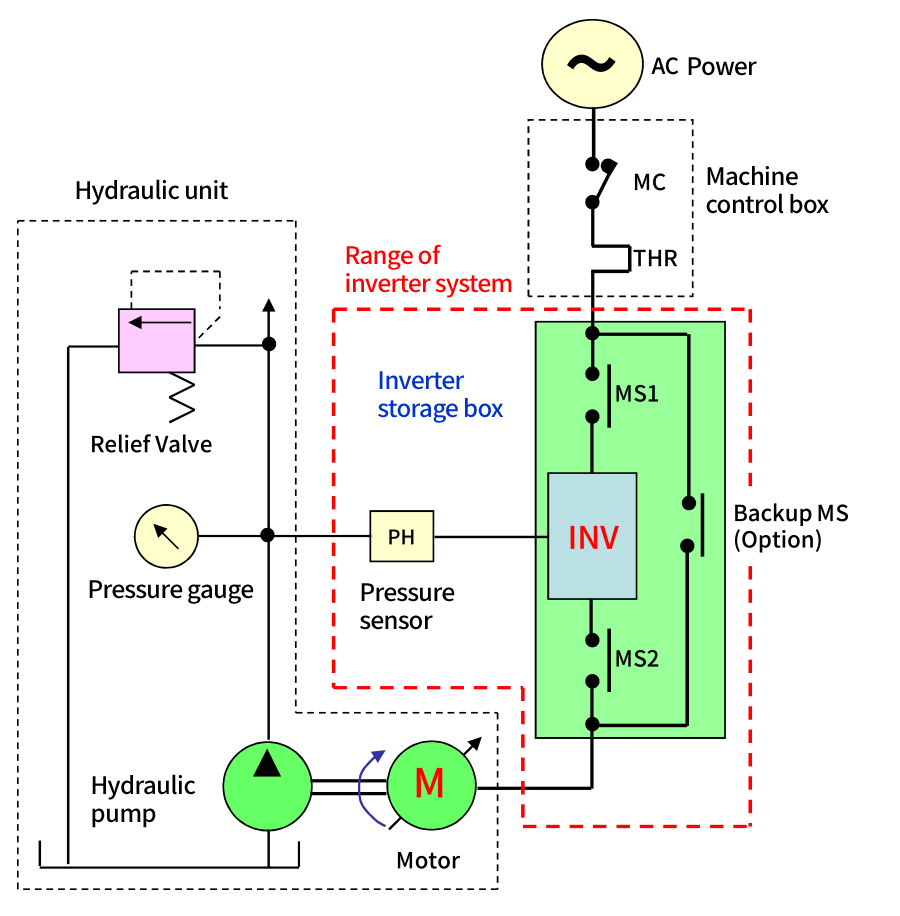

The only additional installation parts are the inverter storage box and pressure sensor, so the hydraulic unit can be used as is by simply attaching the sensor.

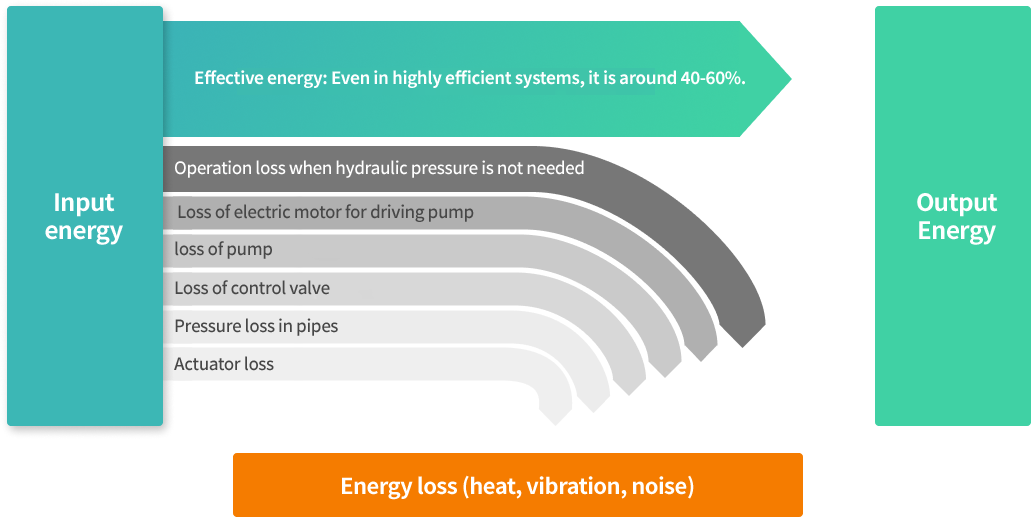

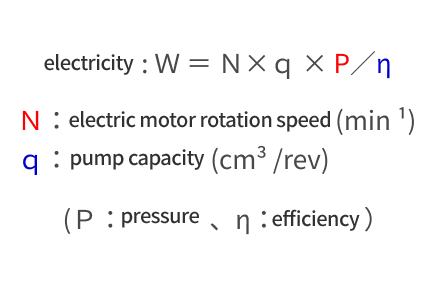

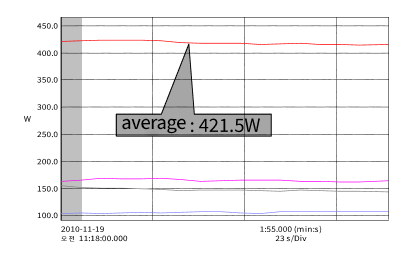

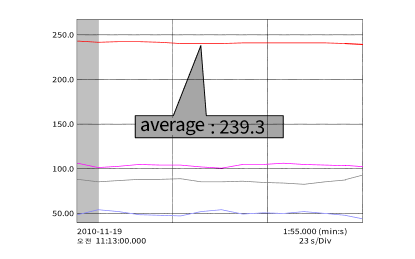

By detecting the pressure maintenance state with a pressure sensor and automatically controlling the rotation speed of the hydraulic pump, power consumption can be significantly reduced in the pressure maintenance (packing pressure) state.

The noise environment of factories is an important environmental issue that must be improved in parallel with energy conservation. In the pressure maintenance (holding pressure) state, the rotation speed of the motor is reduced to the minimum, which not only saves energy but also significantly reduces noise.

By adding a backup function, if a pressure sensor or inverter failure occurs while the inverter is in use, it can be switched to the existing power source and operation can be performed with a simple switch operation, minimizing the impact on the production line and allowing the facility to continue operating.

Even in countries where the input voltage is 50HZ, when the HIT system is attached, the output does not require a 60HZ MOTOR or PUMP step up.

Annual CO2

reduction

1.14t

Energy

saving effect

52%

Annual CO2

reduction

1.05t

Energy

saving effect

43%

| motor capacity | Power consumption per hour | Annual power consumption | Yearly savings | |||||

|---|---|---|---|---|---|---|---|---|

| Normal UNIT | Eco UNIT | Normal UNIT | Electricity amount | Eco UNIT | Electricity amount | Saving amount | Savings rate | |

| 2.2KW | 1.7KW | 0.58KW | 7,140KW | 856,800KRW | 2,436KW | 292,320KRW | 564,480KRW | 65.8% |

| 3.7KW | 2.9KW | 0.65KW | 12,180KW | 1,461,600KRW | 2,730KW | 327,600KRW | 1,134,000KRW | 77.6% |

| 5.5KW | 5.2KW | 0.9KW | 21,840KW | 2,620,800KRW | 3,780KW | 453,600KRW | 2,167,200KRW | 82.7% |

| 7.5KW | 5.6KW | 1.2KW | 23,520KW | 2,822,400KRW | 5,040KW | 604,800KRW | 2,217,600KRW | 78.6% |

| 11KW | 5.7KW | 0.7KW | 23,940KW | 2,872,800KRW | 2,940KW | 352,800KRW | 2,520,000KRW | 87.7% |

| 15KW | 8.1KW | 1.2KW | 34,020KW | 4,082,400KRW | 5,040KW | 604,800KRW | 3,477,600KRW | 85.2% |